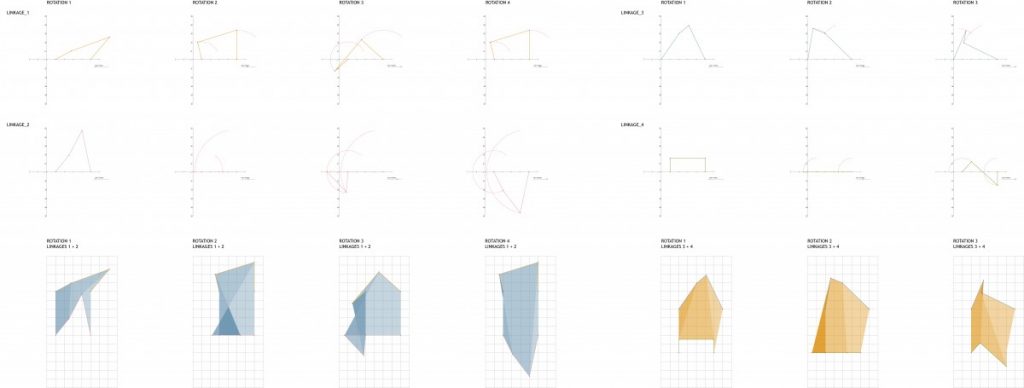

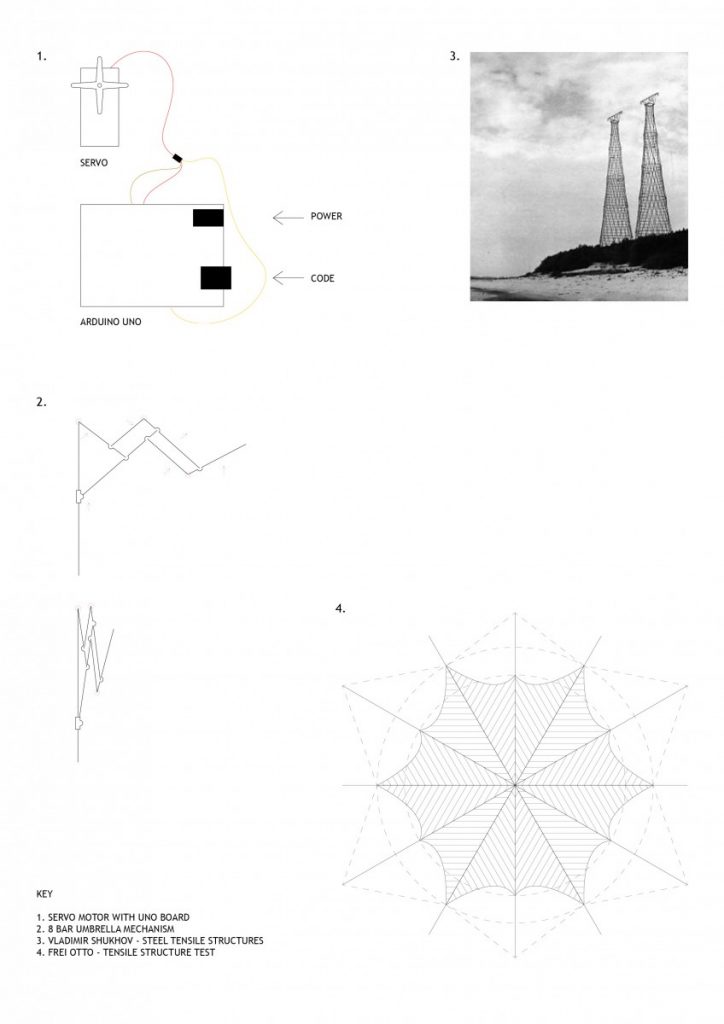

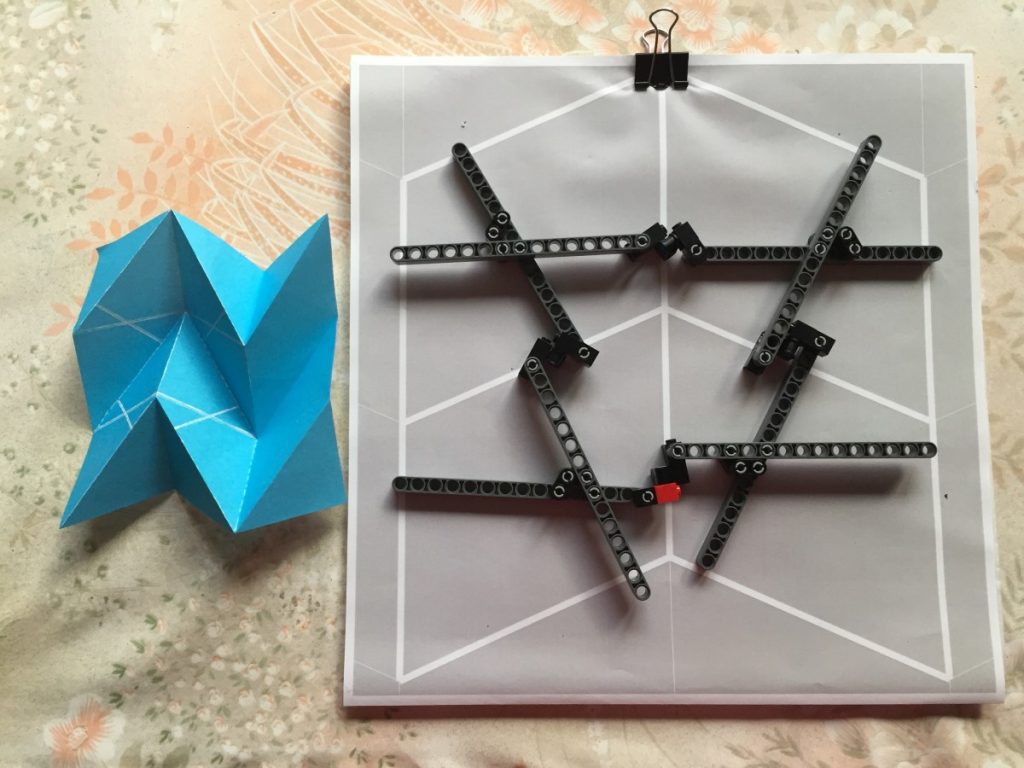

In the previous exploration we observed the spatial and form giving possibilities of the four bar linkage when combined with the servo motor.

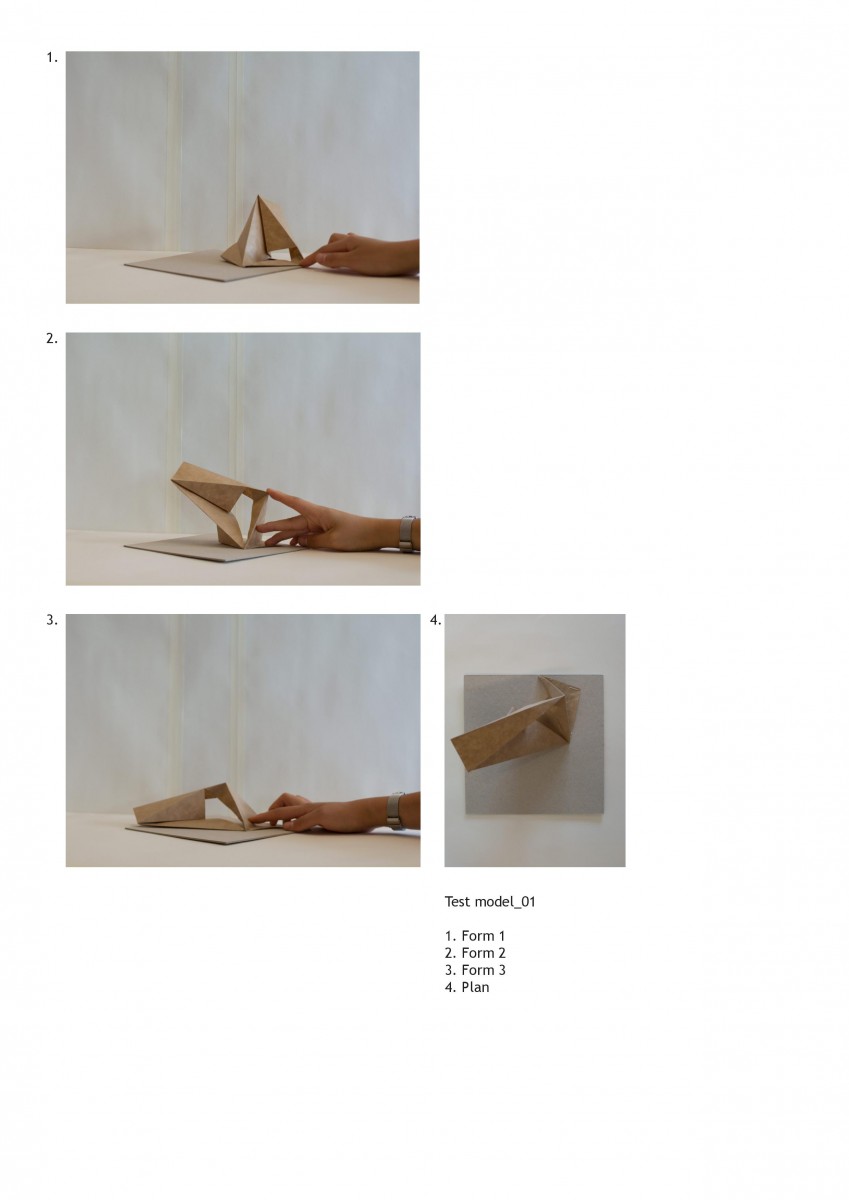

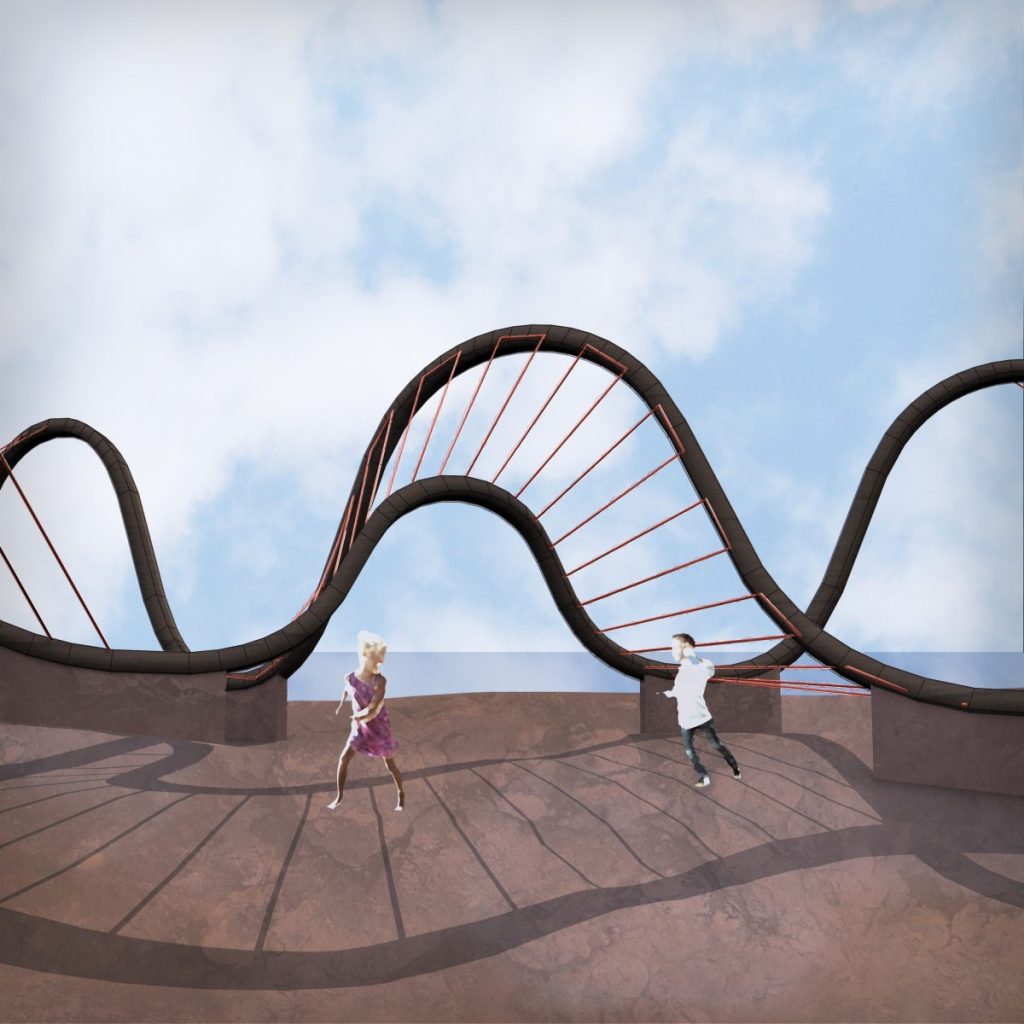

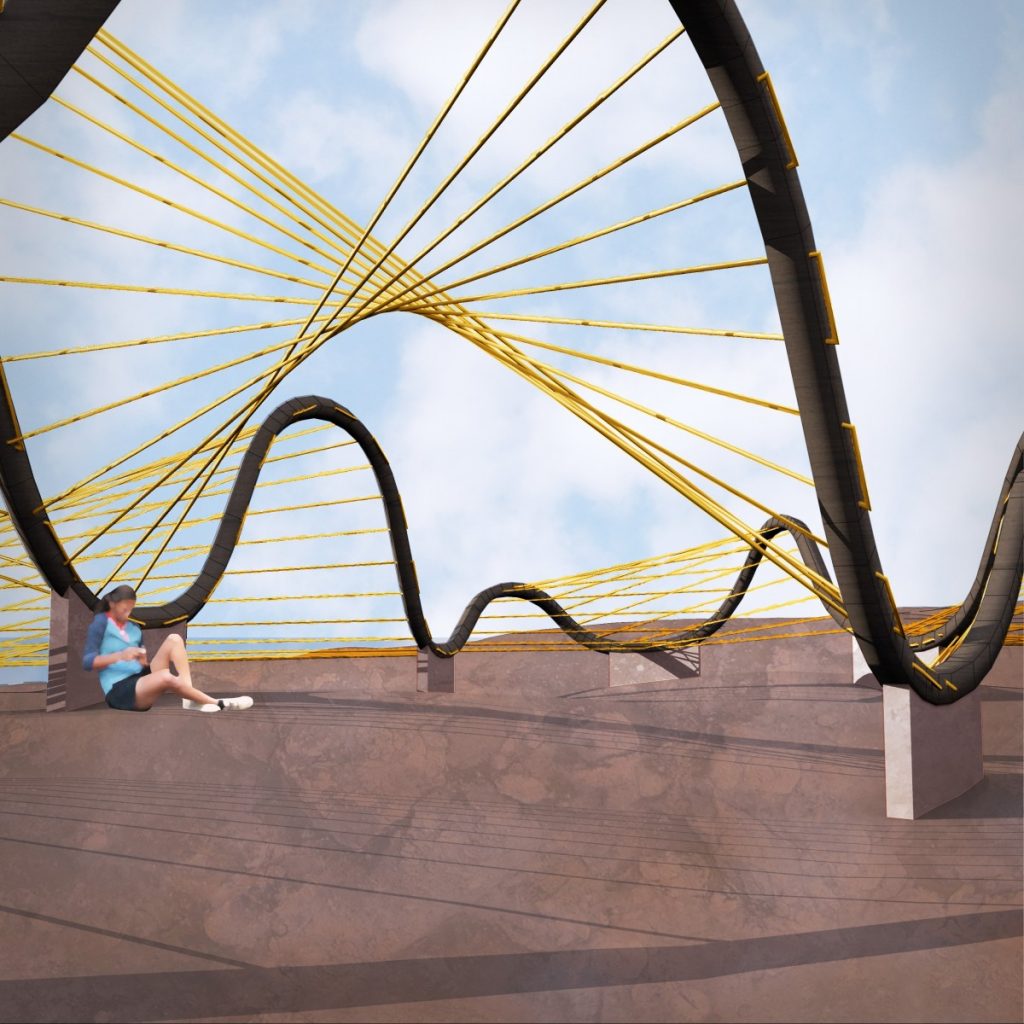

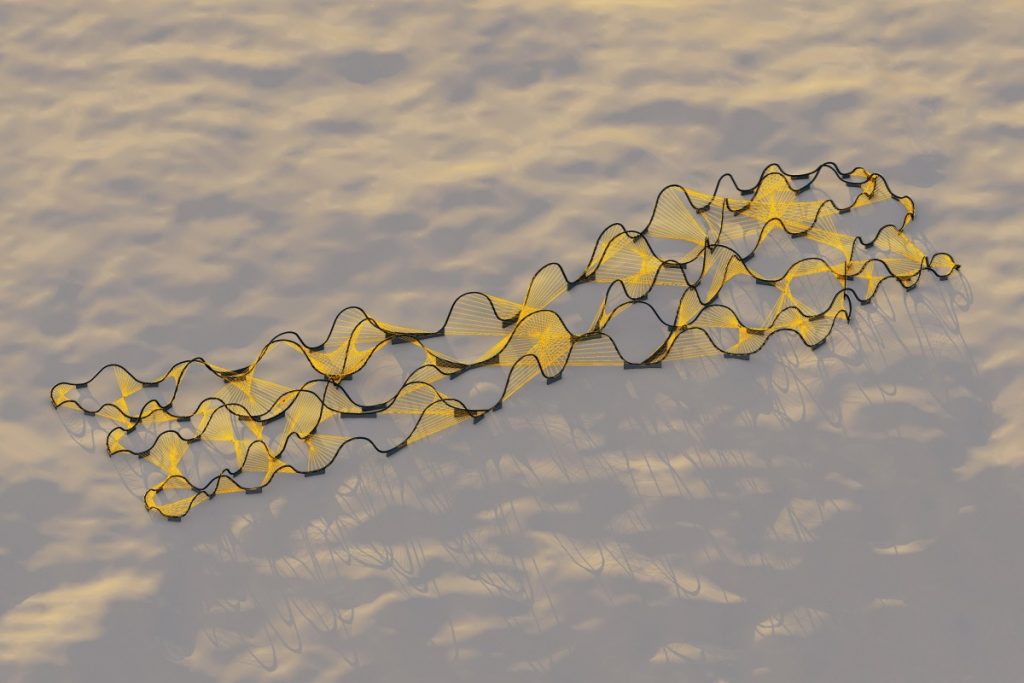

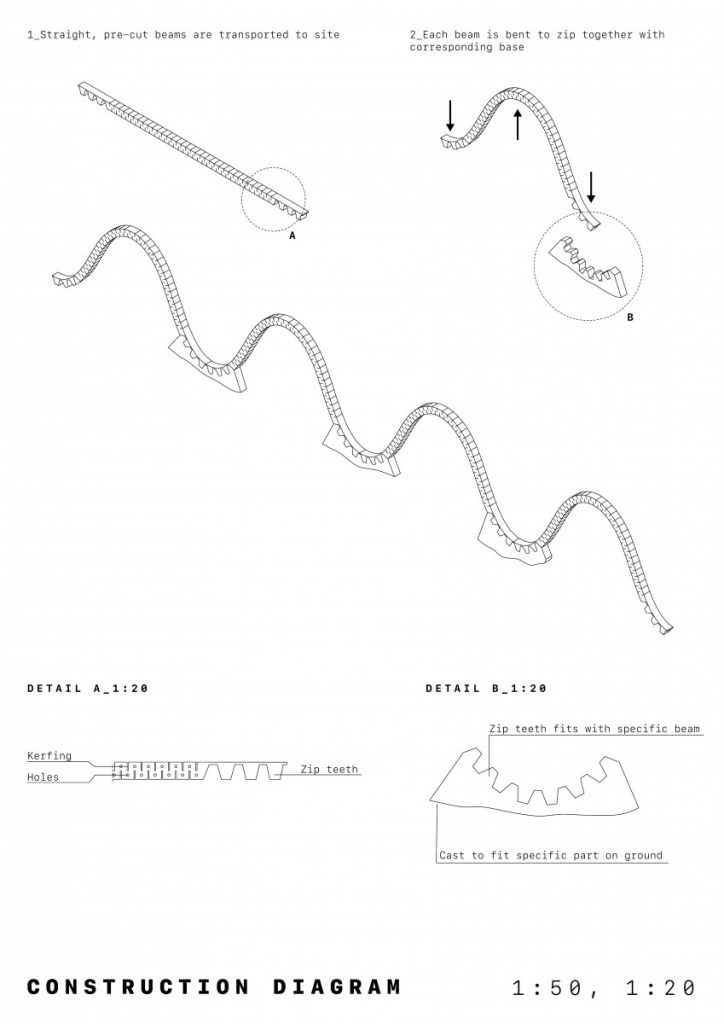

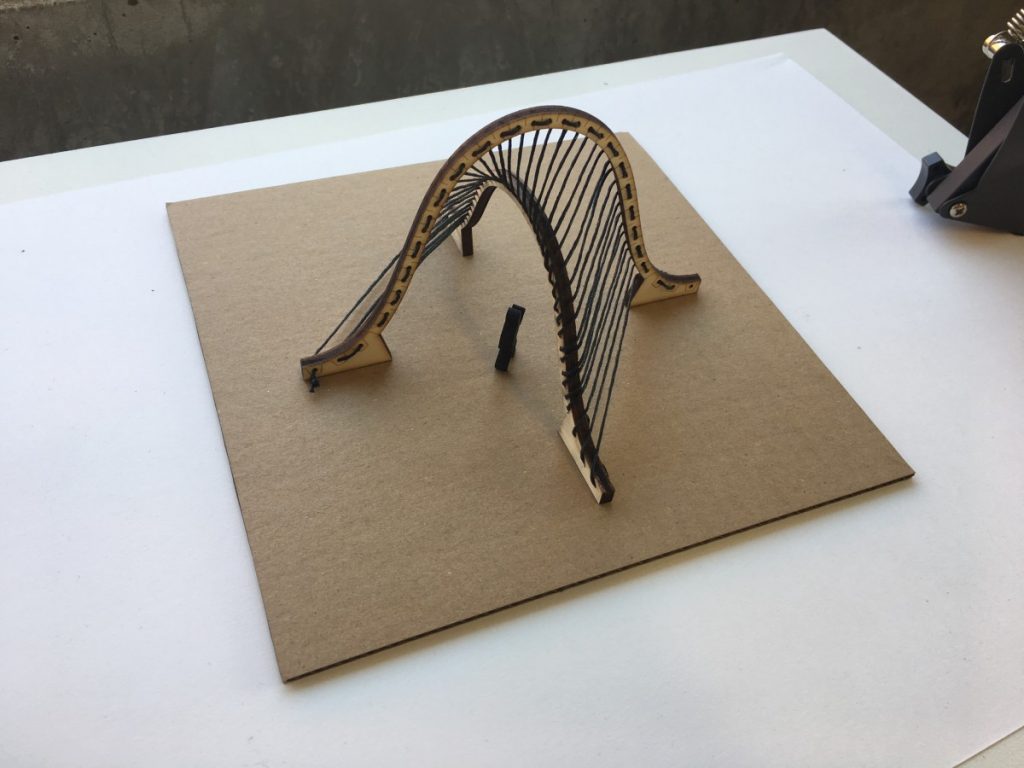

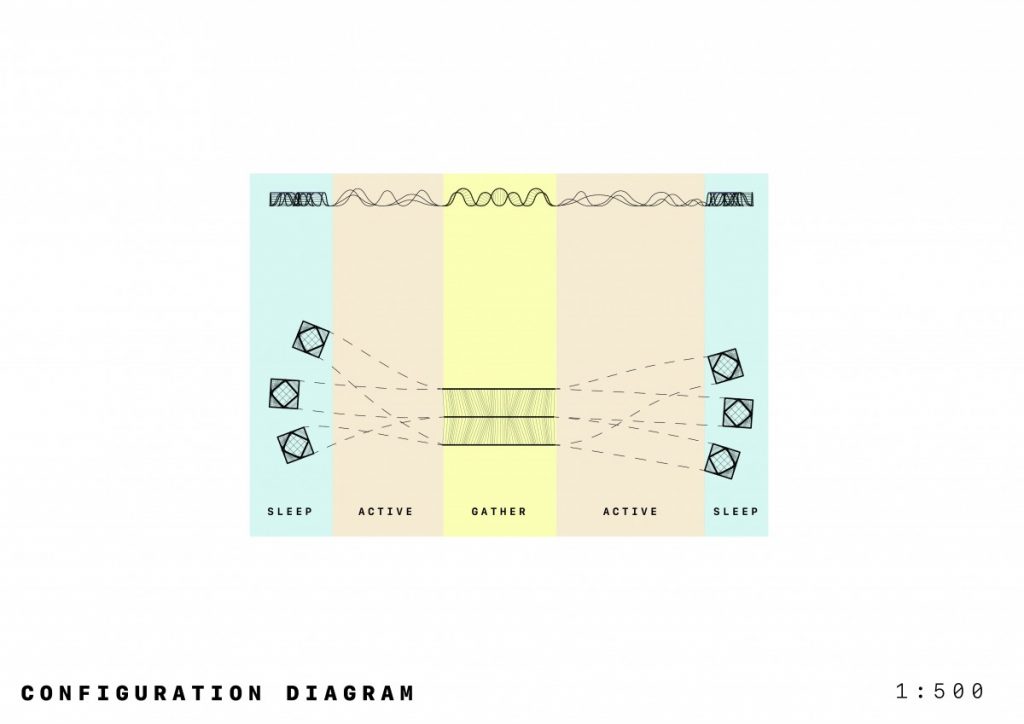

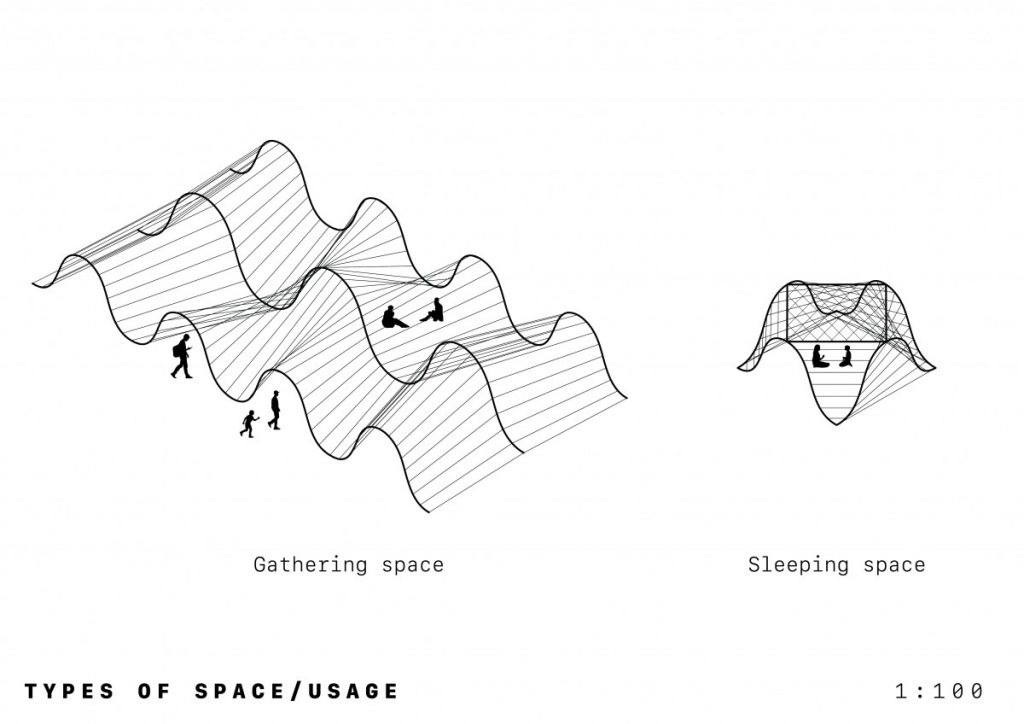

The first test was a planar study of space and allows a reading in plan and in section along a flat plane. When we bring in ideas of tectonics and thickness, we can easily extrude up and allow our architectural judgement to build on from this point.

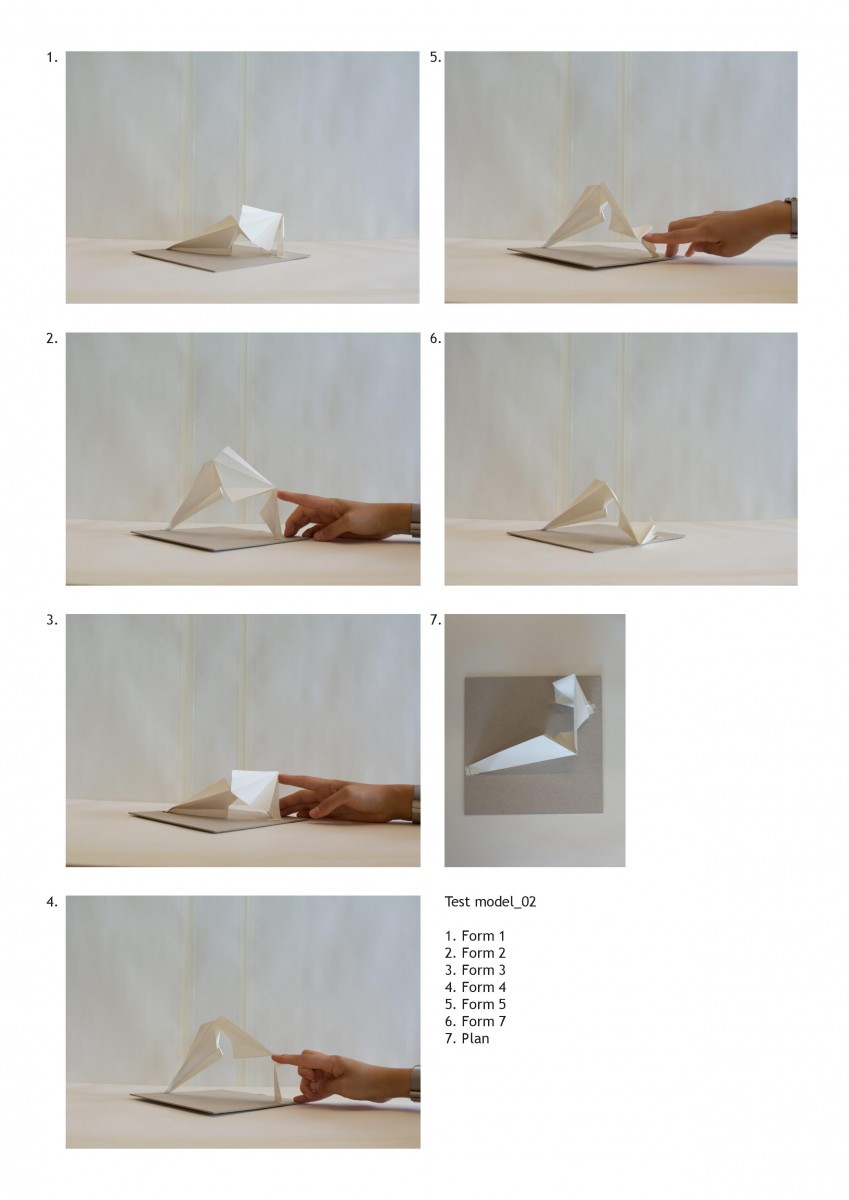

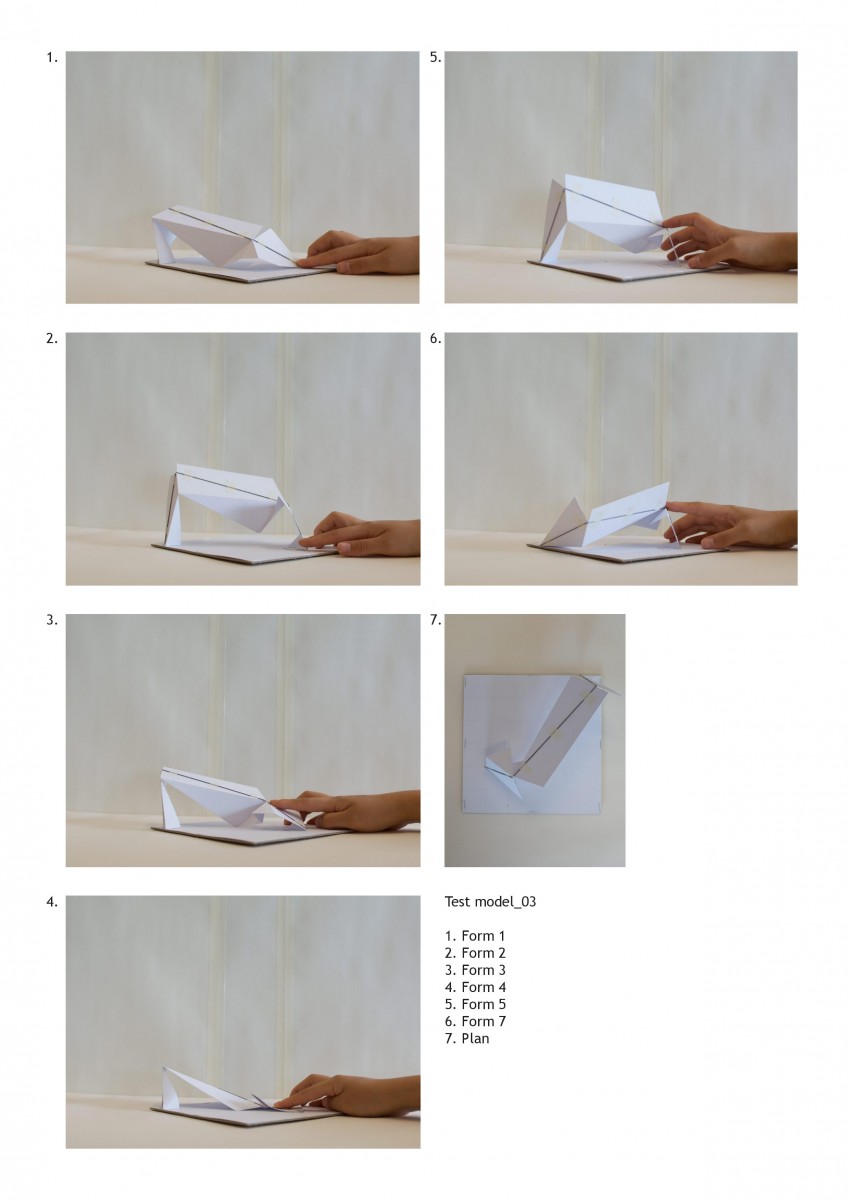

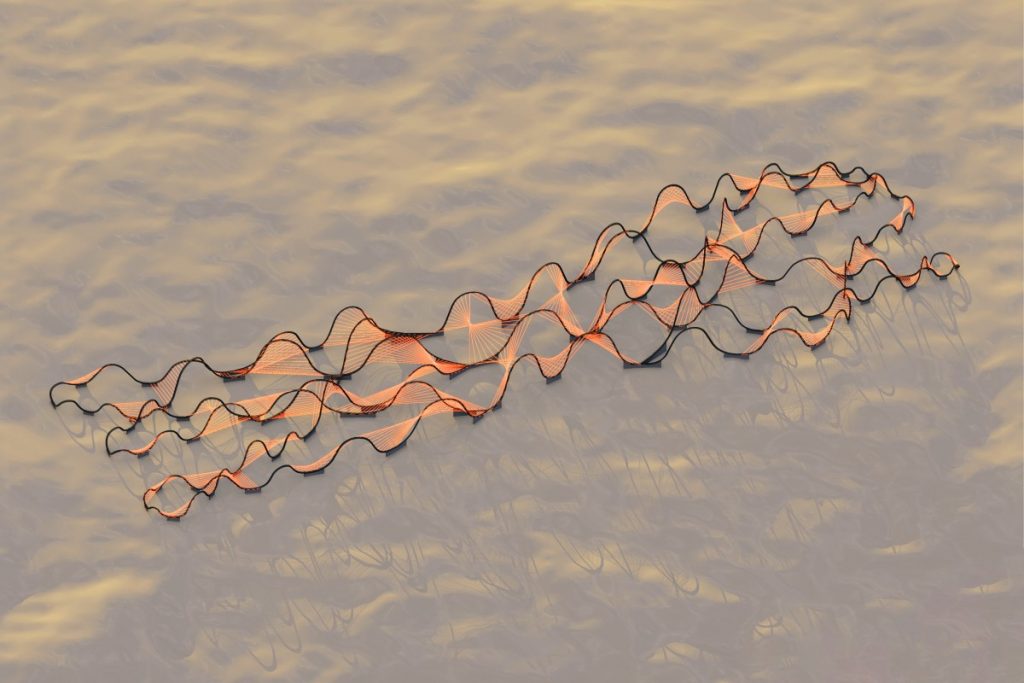

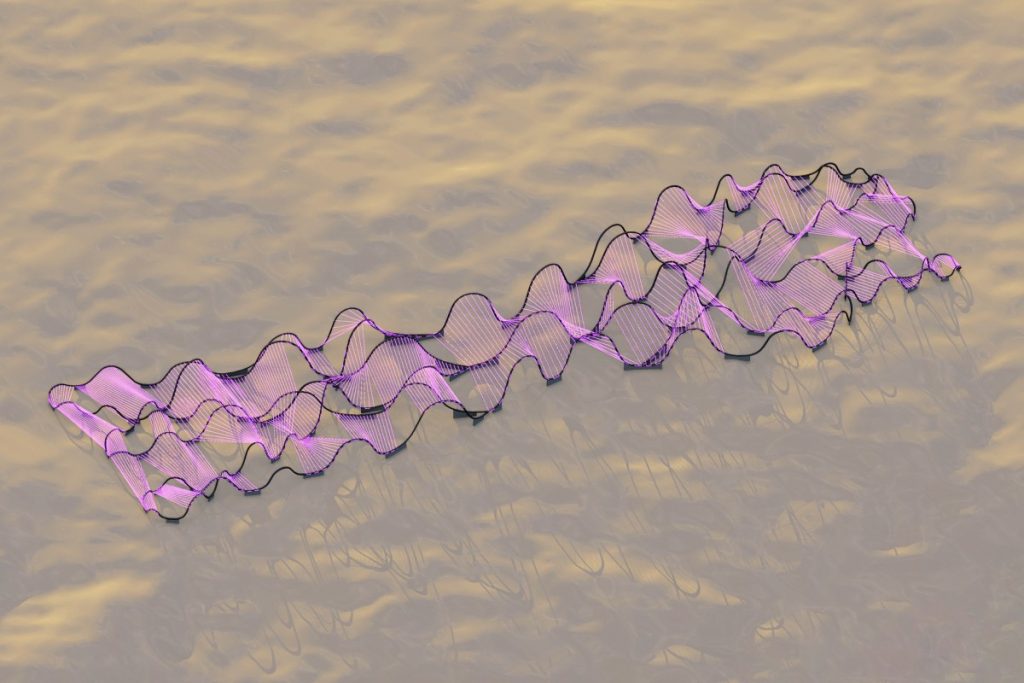

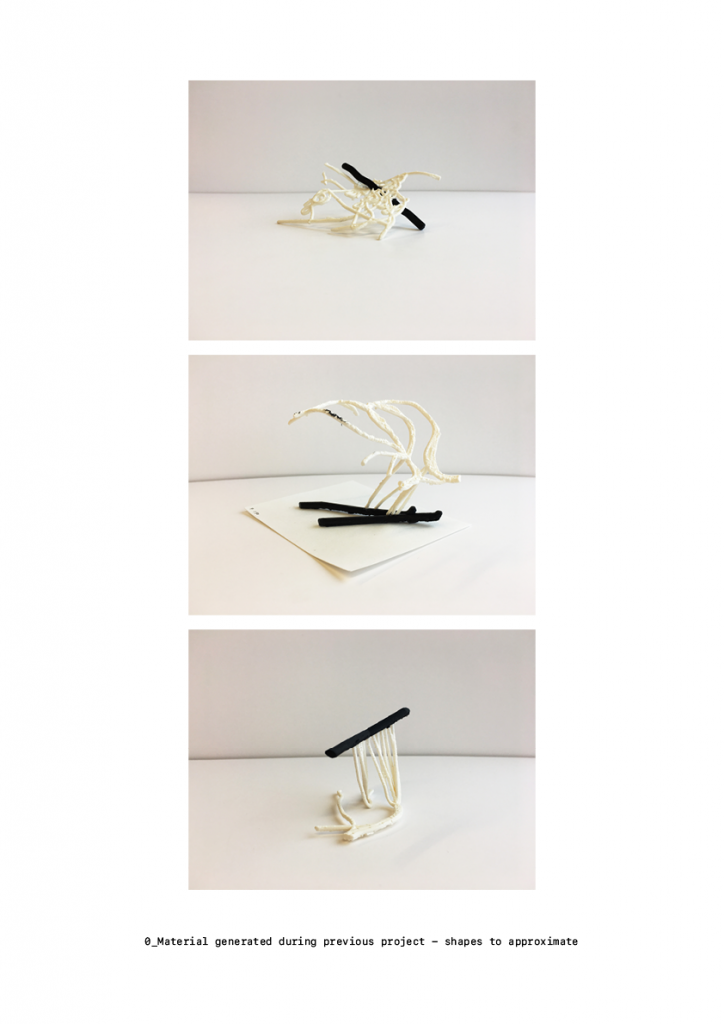

The second test was a study in multiple dimensions and axis. Attempting to assign material qualities was a challenge and therefore this direction seemed like a viable path to further explore.

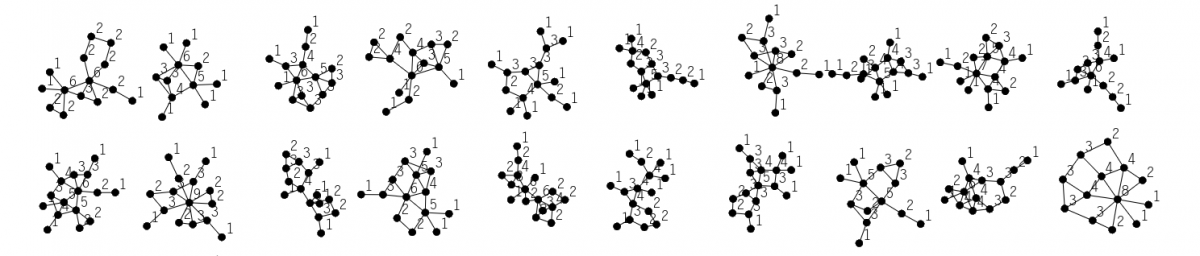

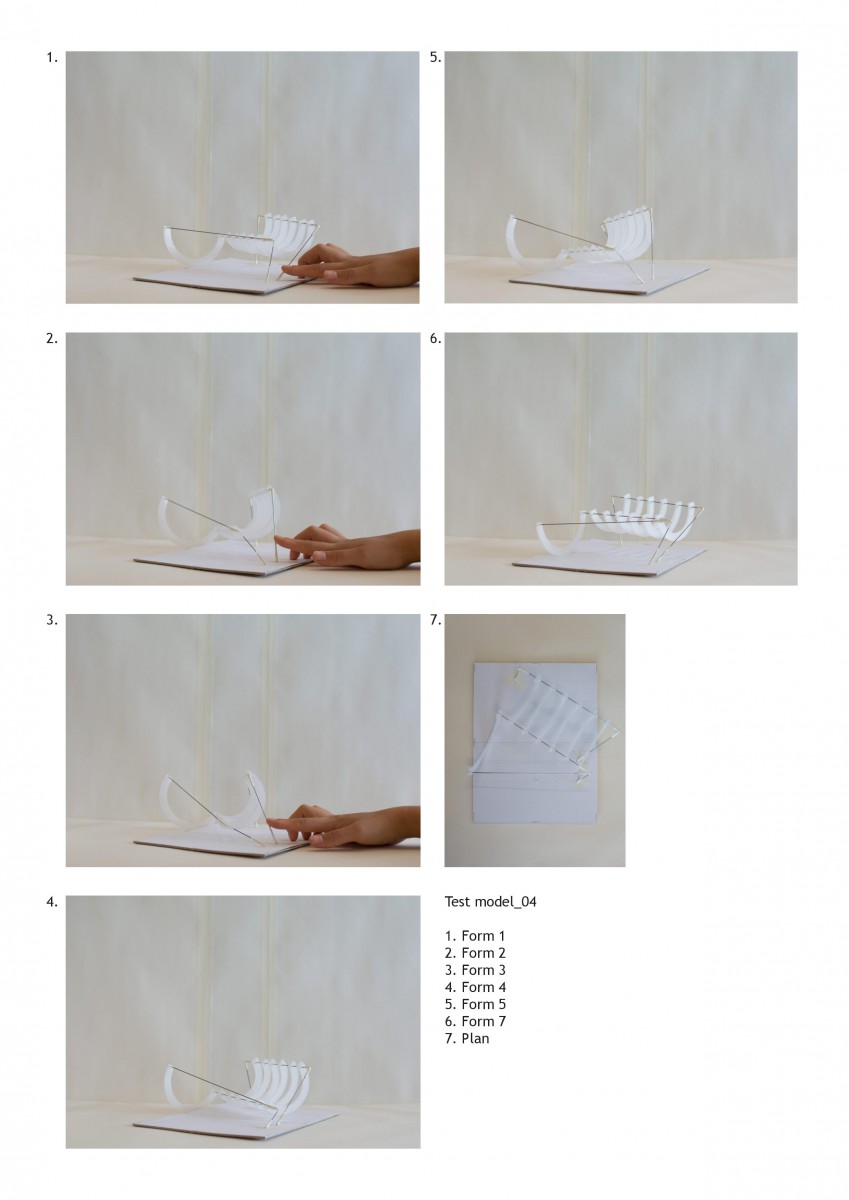

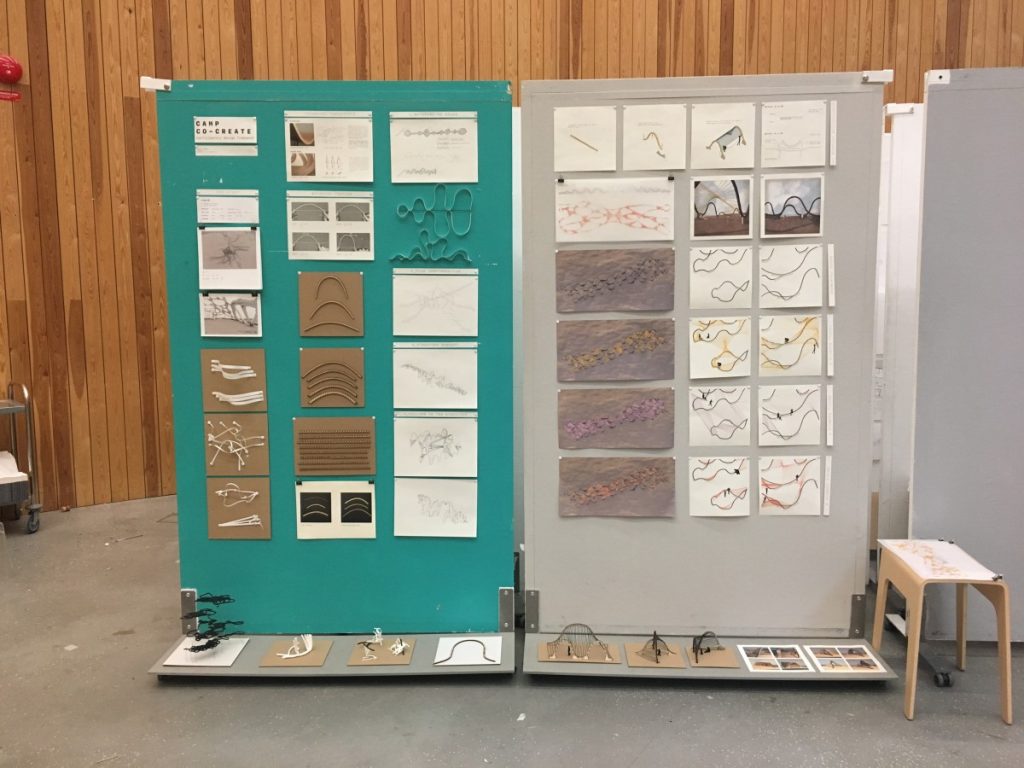

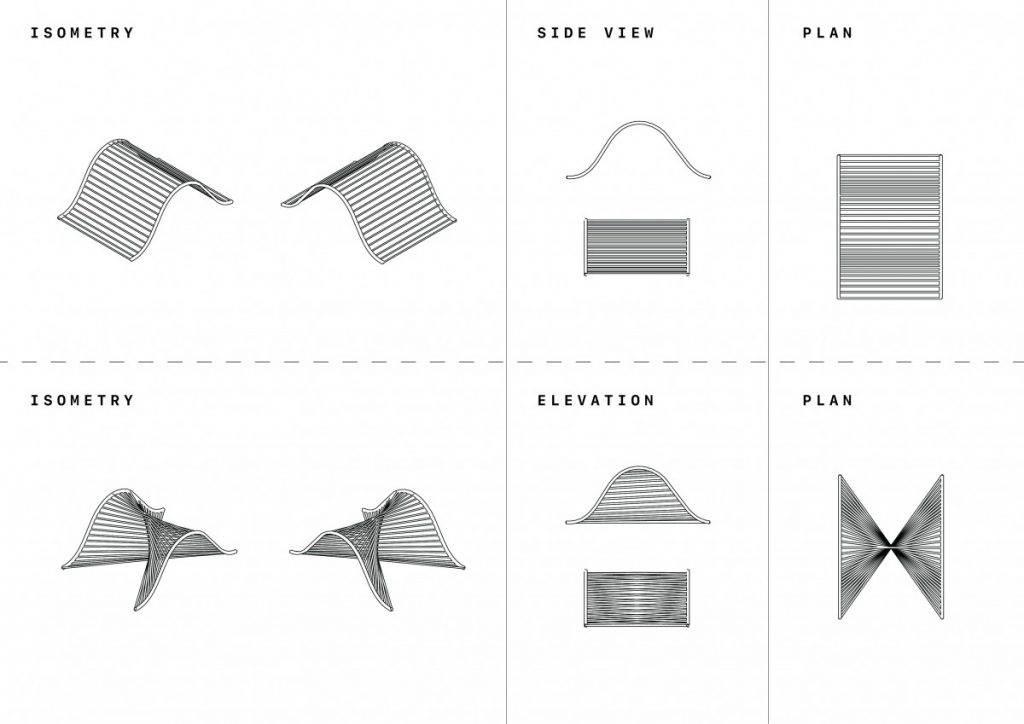

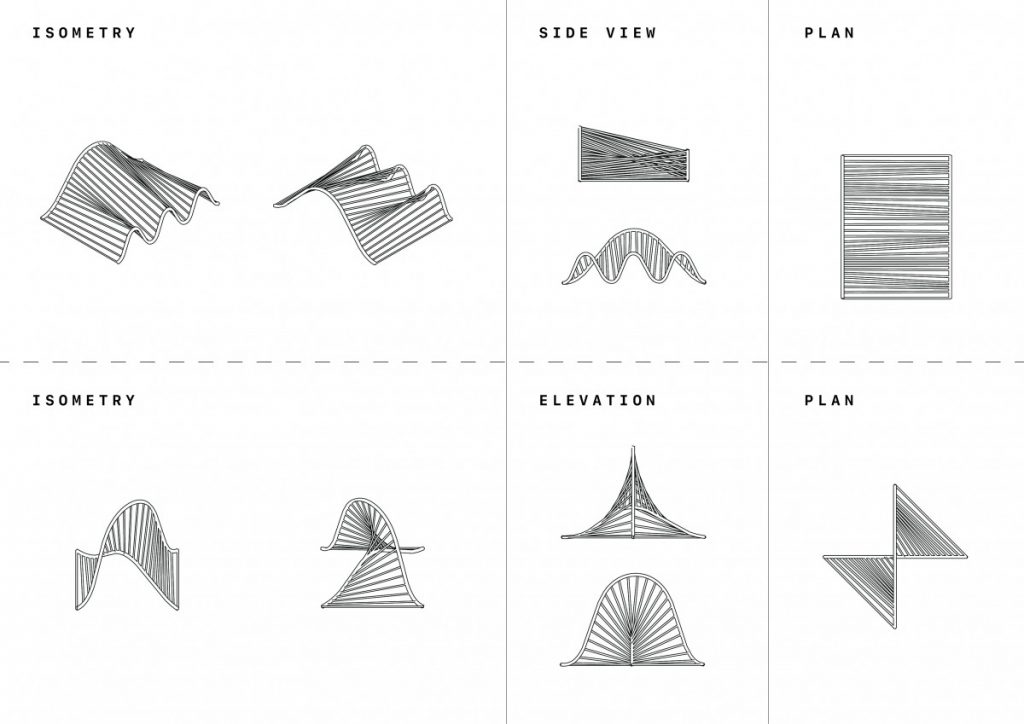

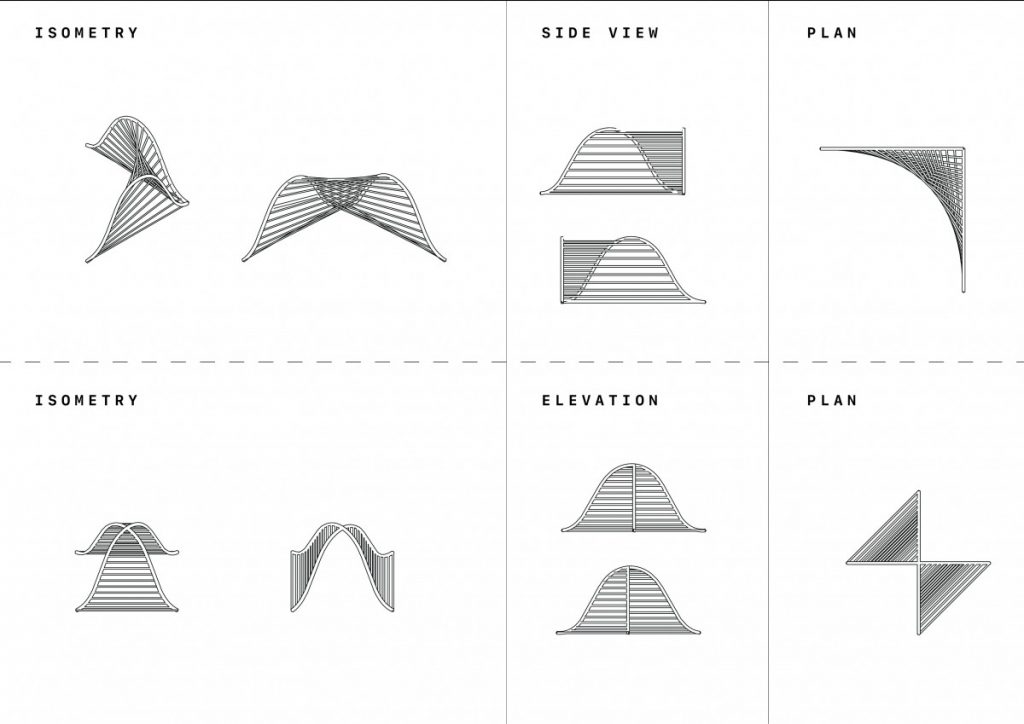

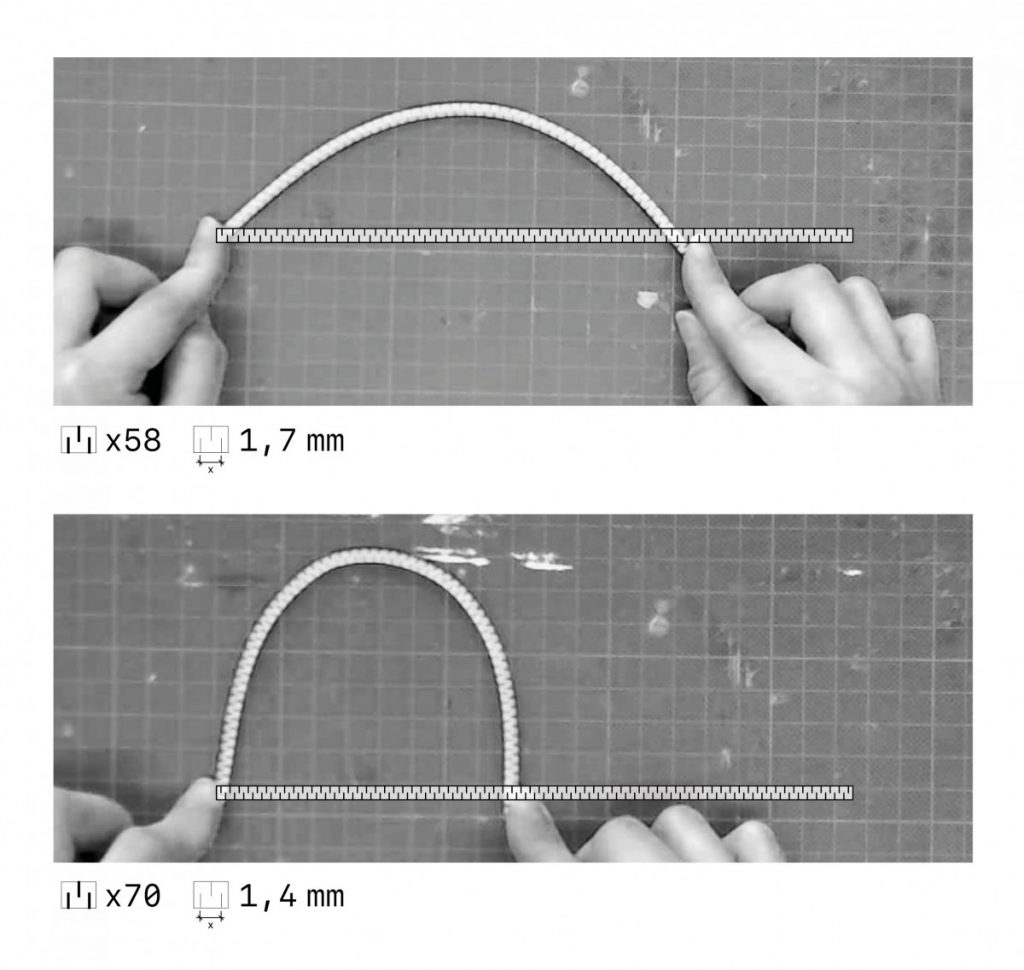

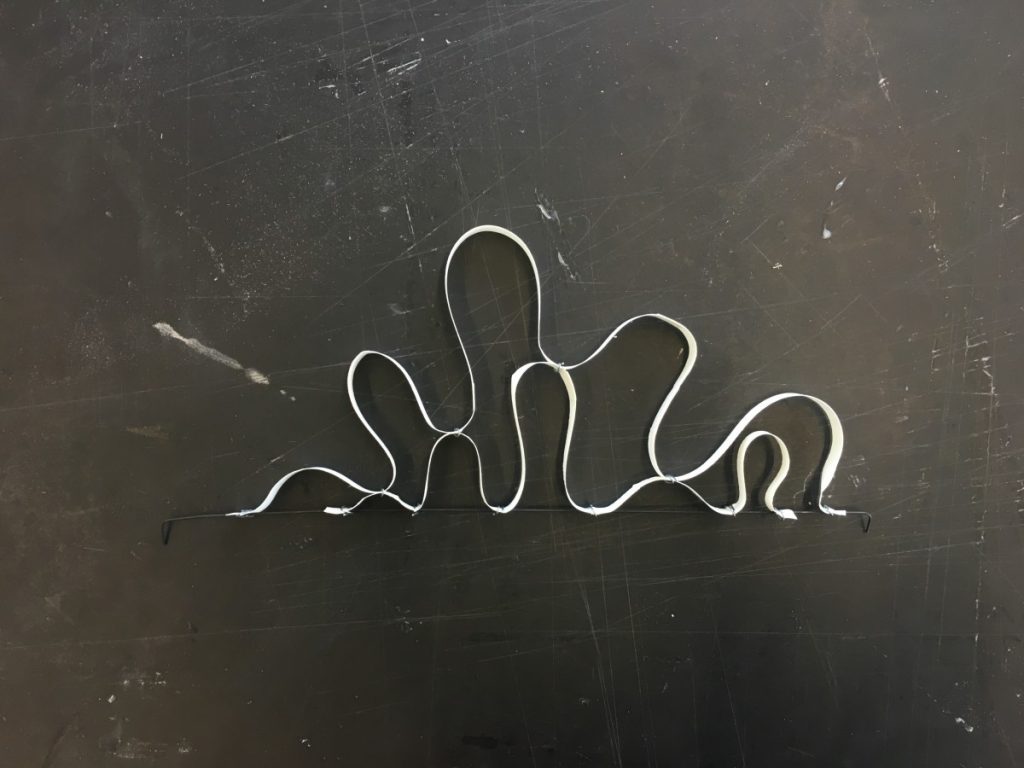

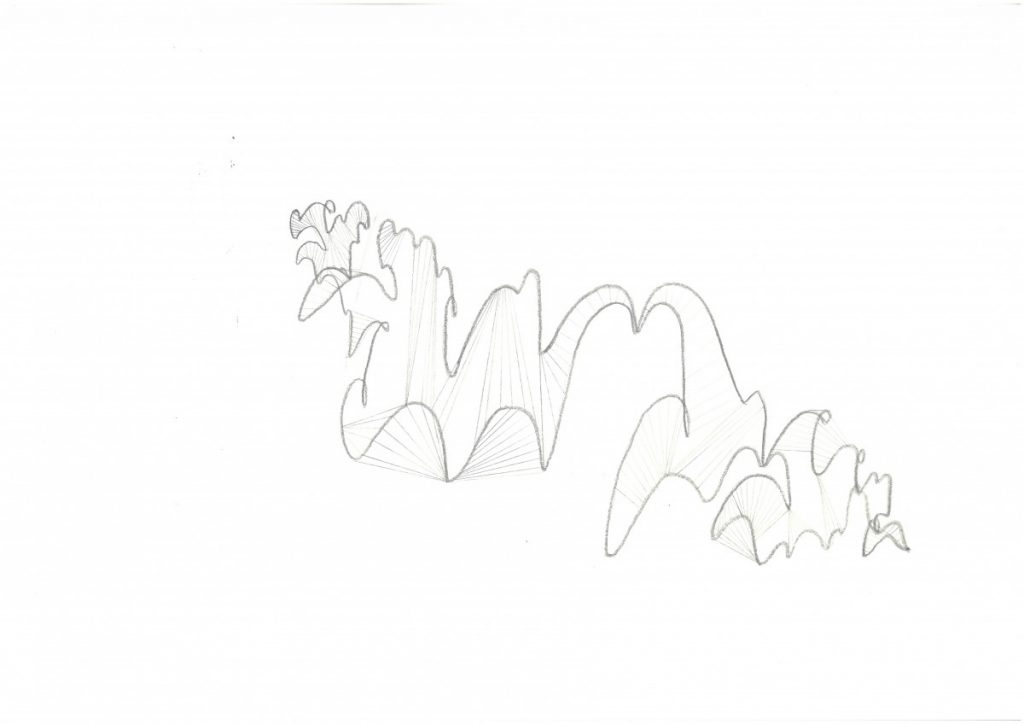

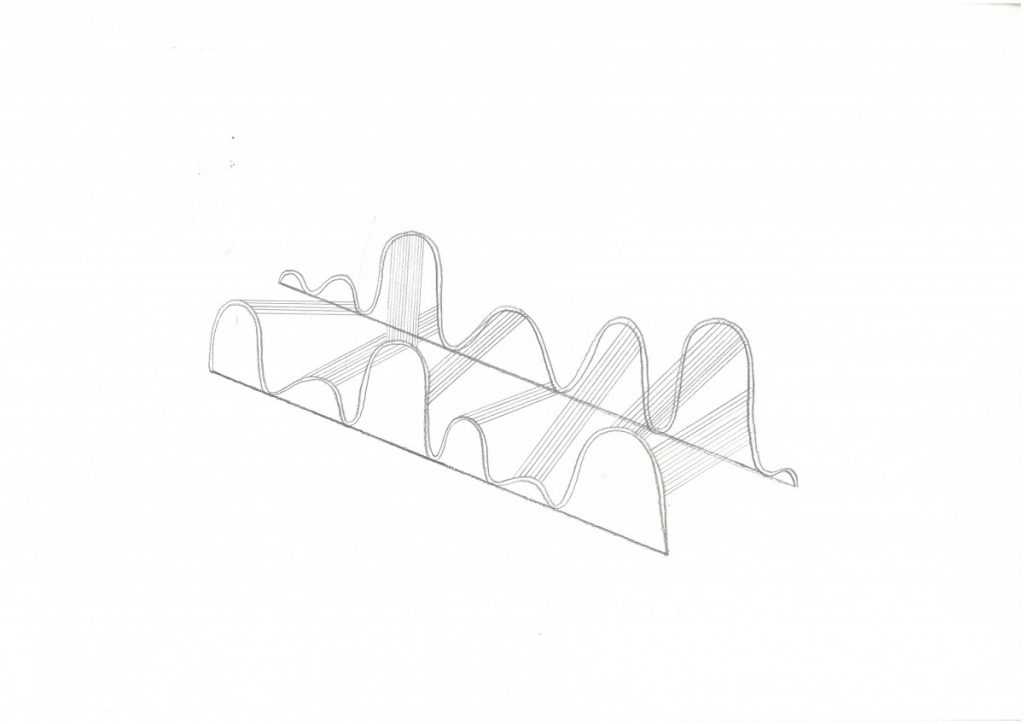

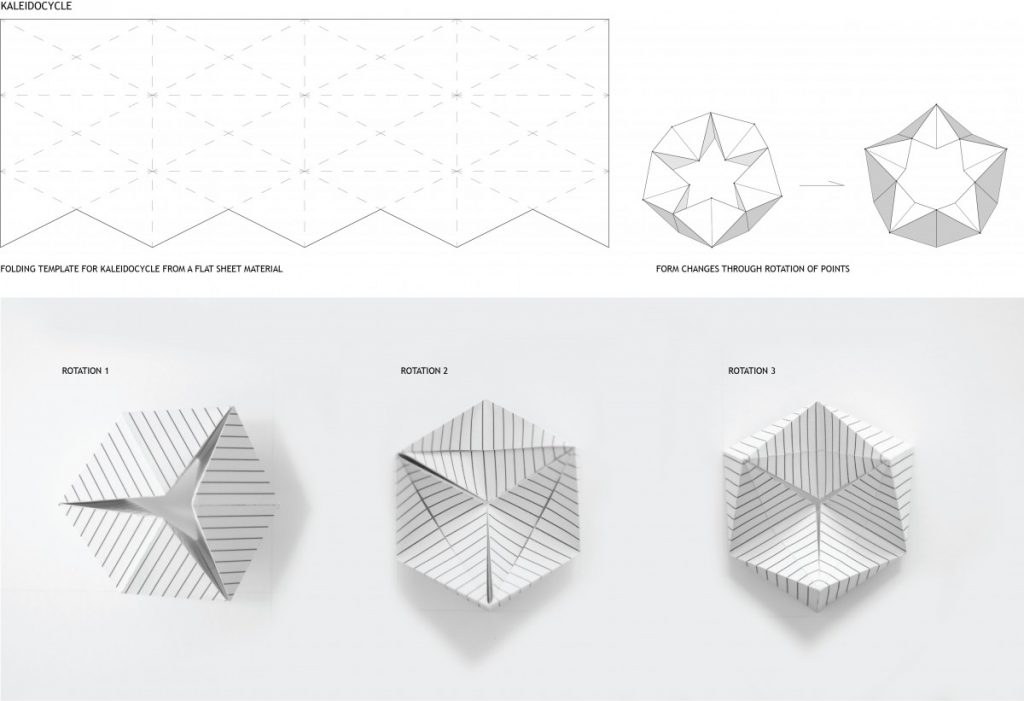

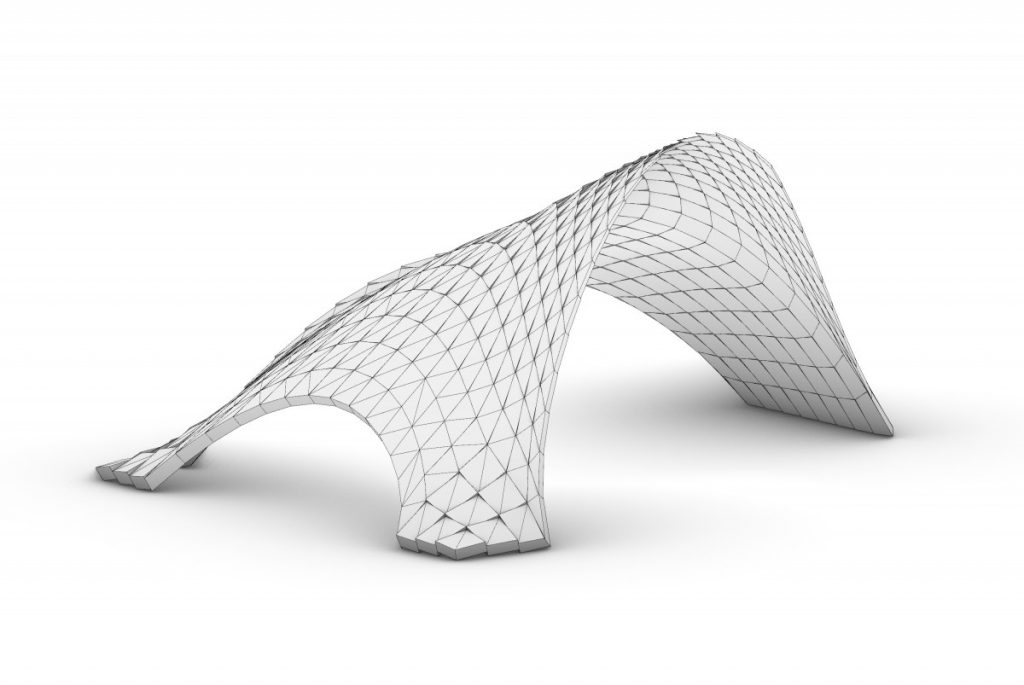

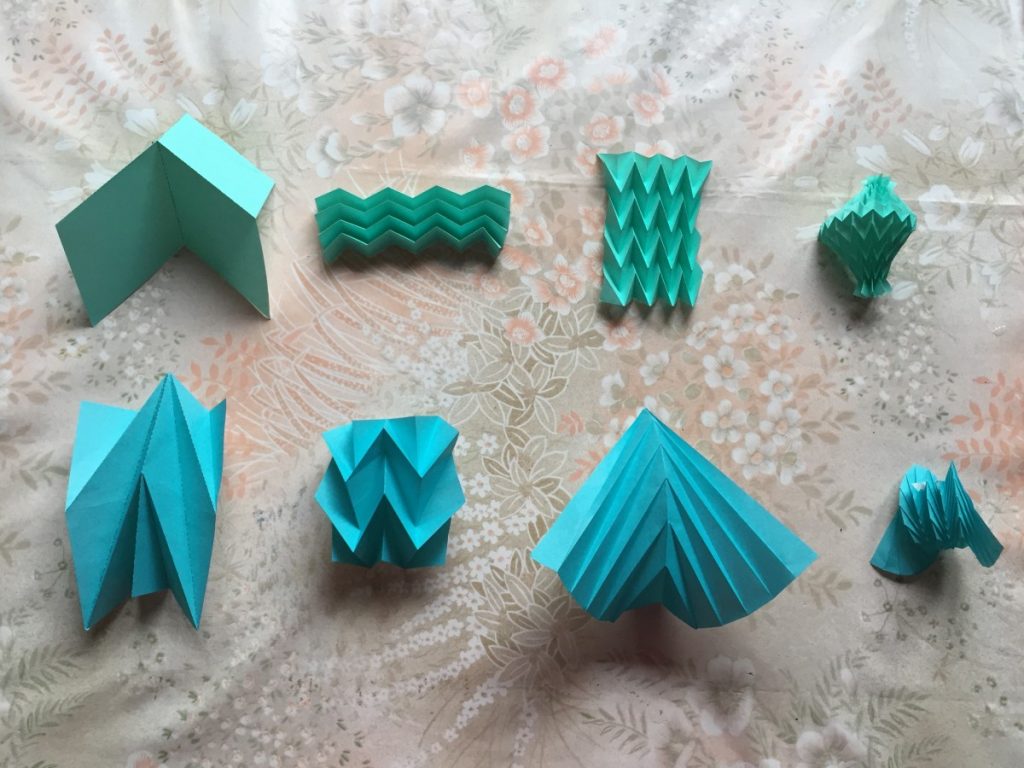

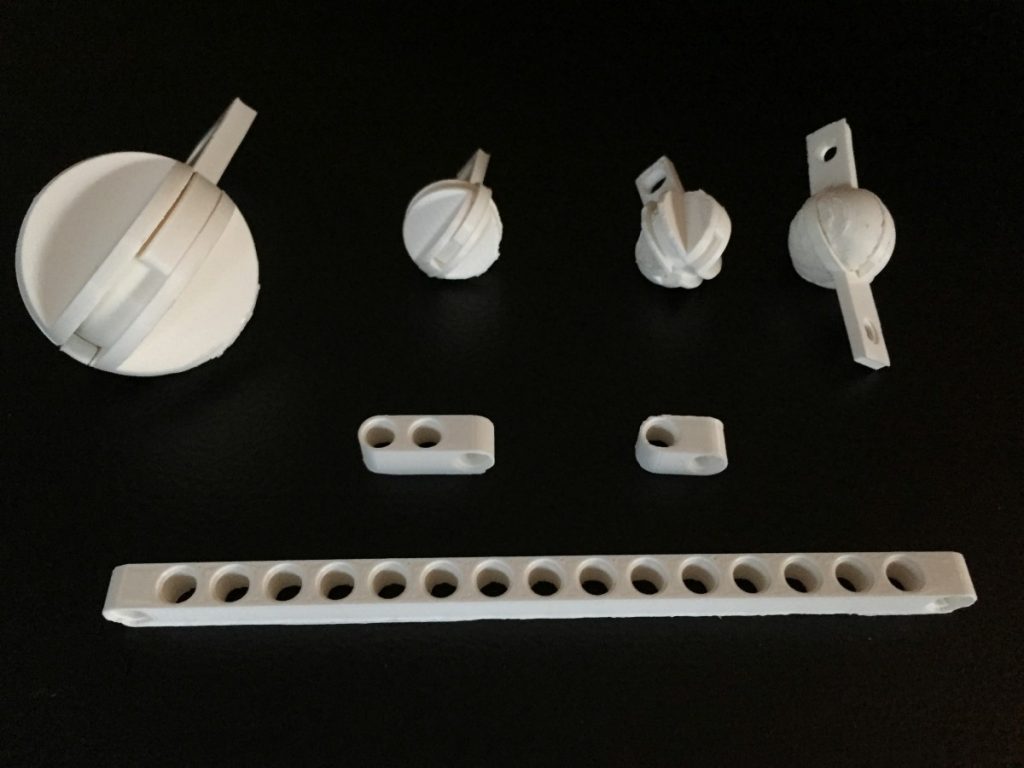

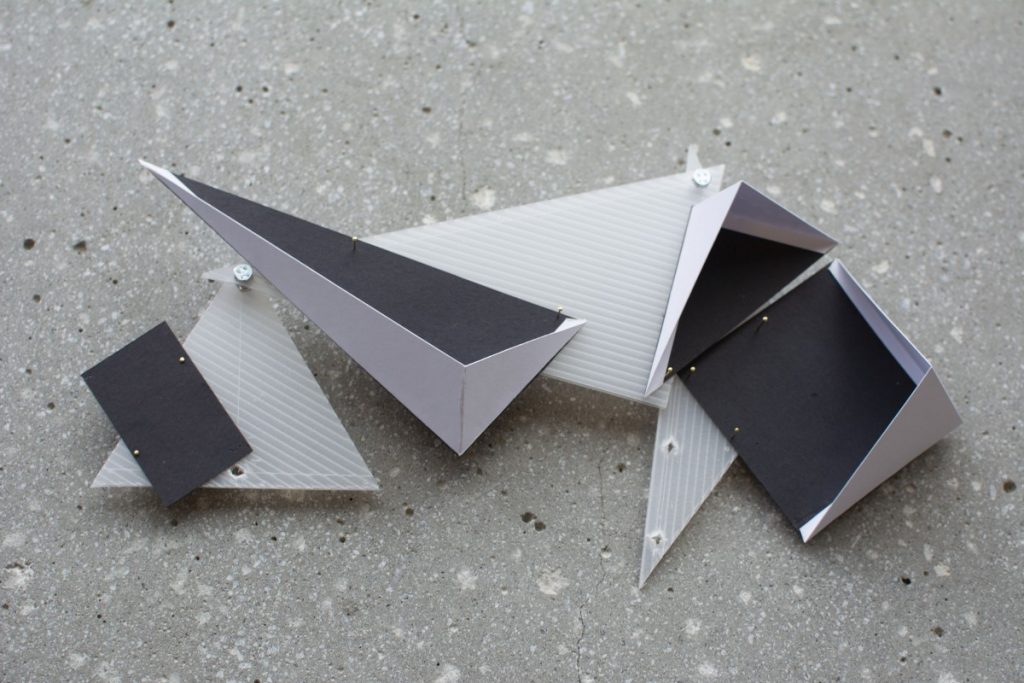

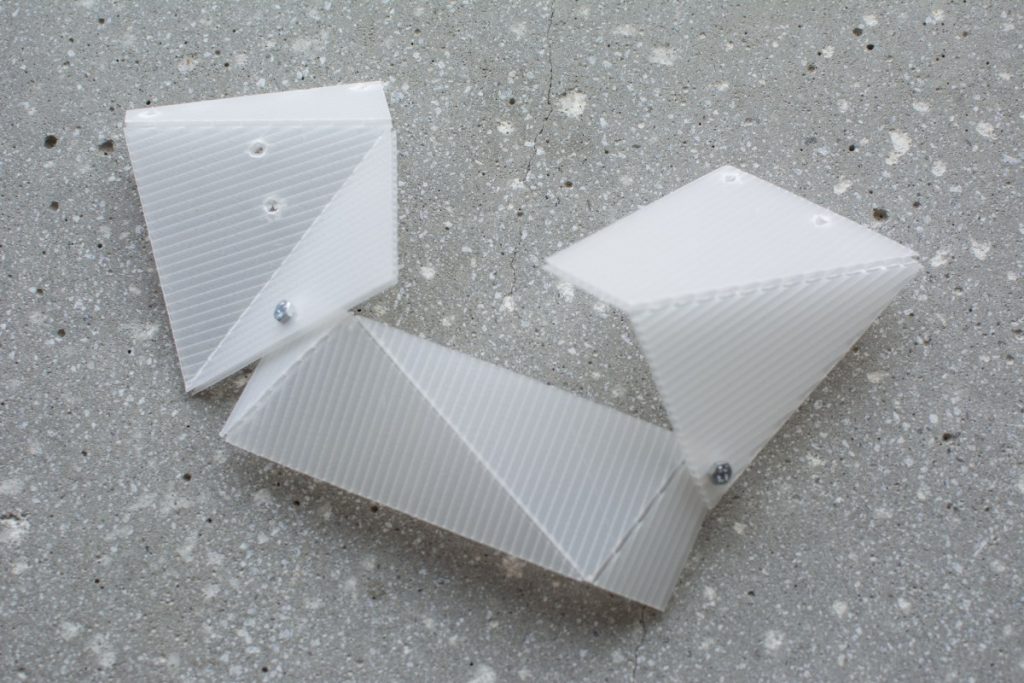

I decided to move the project forward by testing the idea of the four bar linkage across varying planes through simple paper models.

Each of these tests brought about questions of stability, connection points, anchor points, material qualities, thickness, how it meets the ground etc. Potential for the use of colour, thickness and additional elements that extend out from the four bars themselves can be observed. Although a prototype could be developed exploring a solution for such possibilities, I have not been able to push this study to that extent.

Project 3 and 4 has been a sort of research project into robotics, motorised movement and the exploration of what this other world of mobility can offer architecture. No end result as such was assigned throughout the process and I feel that that has allowed me to really understand the possibilities of these tools. I have hit many walls and found myself immersed in frustrations over what architectural meaning this project presents but overall, it has been incredibly fun and challenging taking an alternative approach to architectural design.